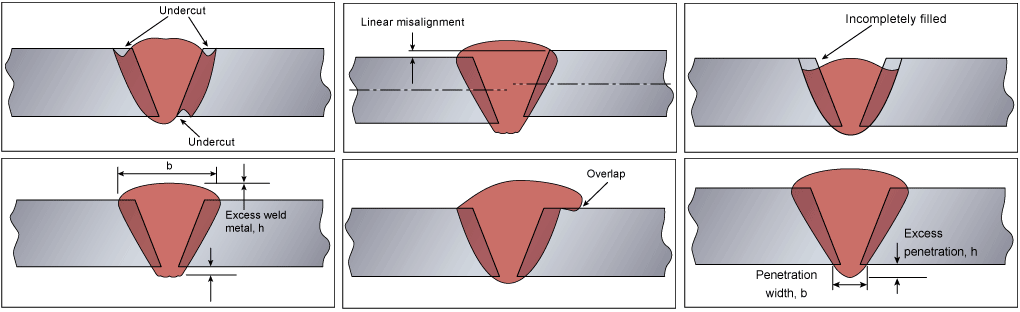

This article looks at those imperfections related to poor geometric shape and will concentrate on the following:

- Excess weld metal

- Undercut

- Overlap

- Linear misalignment

- Incompletely filled groove

- Excessive Penetration

- Root Concavity

Such imperfections might be considered as anomalies in the joint and they will always be present to some degree so that it becomes necessary to separate the acceptable from the unacceptable. This is done by following guidance given by the application standard, which was the basis for the component design, and/or by direction, as set out in the job contract. Examples of standards that might be referred to are:

- PD 5500 Specification for unfired fusion welded pressure vessels.

- BS 2640 Specification for Class II oxy-acetylene welding of carbon steel pipework for carrying fluids

- BS EN 25817 Arc welded joints in steel - guidance on quality levels for imperfections

- AWS D1.1 Structural welding code - Steel

TQ very much.i had studied your welding defects.tq

ReplyDelete