The hardness of a material can have a number of meanings depending upon the context, which in the case of metals generally means the resistance to indentation. There are a number of test methods of which only the Brinell, Vickers and portable hardness testing will be covered in this article.

Brinell Hardness Test

The Brinell test was devised by a Swedish researcher at the beginning of the 20th century. The test comprises forcing a hardened steel ball indentor into the surface of the sample using a standard load as shown in Fig.1(a). The diameter/load ratio is selected to provide an impression of an acceptable diameter. The ball may be 10, 5 or 1mm in diameter, the load may be 3000, 750 or 30kgf, The load, P, is related to the diameter, D by the relationship P/D 2 and this ratio has been standardised for different metals in order that test results are accurate and reproducible. For steel the ratio is 30:1 - for example a 10mm ball can be used with a 3000kgf load or a 1mm ball with a 30kgf load. For aluminium alloys the ratio is 5:1. The load is applied for a fixed length of time, usually 30 seconds. When the indentor is retracted two diameters of the impression, d 1 and d 2 , are measured using a microscope with a calibrated graticule.and then averaged as shown in Fig.1(b).

|

| Fig.1. Brinell Hardness Test |

The Brinell hardness number (BHN) is found by dividing the load by the surface area of the impression. There is a somewhat tedious calculation that can be carried out to determine the hardness number but it is more usual and far simpler to refer to a set of standard tables from which the Brinell hardness number can be read directly.

The Brinell test is generally used for bulk metal hardness measurements - the impression is larger than that of the Vickers test and this is useful as it averages out any local heterogeneity and is affected less by surface roughness. However, because of the large ball diameter the test cannot be used to determine the hardness variations in a welded joint for which the Vickers test is preferred. Very hard metals, over 450BHN may also cause the ball to deform resulting in an inaccurate reading. To overcome this limitation a tungsten carbide ball is used instead of the hardened steel ball but there is also a hardness limit of 600BHN with this indentor.

Vickers Hardness Test

|

| Fig.2. Schematic principles of operation of Vickers hardness machine |

The basic principles of operation of the Vickers hardness test are illustrated in Fig.2 where it can be seen that the load is applied to the indentor by a simple weighted lever. In older machines an an oil filled dash pot is used as a timing mechanism - on more modern equipment this is done electronically.

|

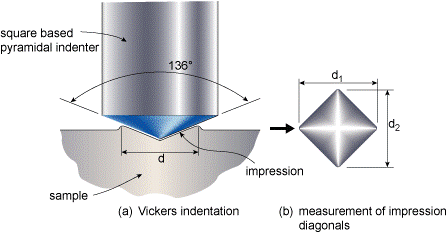

| Fig.3. Vickers hardness test |

As mentioned earlier, the Vickers indentation is smaller than the Brinell impression and thus far smaller areas can be tested, making it possible to carry out a survey across a welded joint, including individual runs and the heat affected zones. The small impression also means that the surface must be flat and perpendicular to the indentor and should have a better than 300 grit finish.

Errors in Hardness Testing

There are many factors that can affect the accuracy of the hardness test. Some of these such as flatness and surface finish have already been mentioned above but it is worth re-emphasising the point that flatness is most important - a maximum angle of approximately ± 1° would be regarded as acceptable.

To achieve the required flatness tolerance and surface finish surface grinding or machining may be necessary. The correct load must be applied and to achieve this there must be no friction in the loading system otherwise the impression will be smaller than expected - regular maintenance and calibration of the machine is therefore essential. The condition of the indentor is crucial - whilst the Vickers diamond is unlikely to deteriorate with use unless it is damaged or loosened in its mounting by clumsy handling, the Brinell ball will deform over a period of time and inaccurate readings will result. This deterioration will be accelerated if a large proportion of the work is on hard materials. The length of time that the load is applied is important and must be controlled.

The specimen dimensions are important - if the test piece is too thin the hardness of the specimen table will affect the result. As a rule of thumb the specimen thickness should be ten times the depth of the impression for the Brinell test and twice that of the Vickers diagonal. Similarly, if the impression is too close to the specimen edge then low hardness values will be recorded - again as a rule the impression should be some 4 to 5 times the impression diameter from any free edge. Performing hardness testing on cylindrical surfaces eg pipes and tubes, the radius of curvature will affect the indentation shape and can lead to errors. It may be necessary to apply a correction factor - this is covered in an ISO specification, ISO 6507 Part 1.

The specimen table should be rigidly supported and must be in good condition - burrs or raised edges beneath the sample will give low readings. Impact loading must be avoided. It is very easy to force the indentor into the specimen surface when raising the table into position. This can strain the equipment and damage the indentor. Operator training is crucial and regular validation or calibration is essential if hardness rest results are to be accurate and reproducible.

Micro-hardness testing may be carried out using any one of three common methods and, as with the macro-hardness tests, measure the size of the impression produced by forcing an indentor into the specimen surface under a dead load, although many of the new test machines use a load cell system.

The three most common tests are the Knoop test, the Vickers test and the ultrasonic micro-hardness test.

The Knoop test uses a pyramidal indentor that gives an elongated diamond shaped impression with an aspect ratio of around 7:1, the Vickers test uses the pyramidal indentor described in the previous article (January/February 2005).

The Knoop test is rarely used in Europe where the Vickers test is the preferred method. The loads used for the tests vary from 1gmf to 1kgf and produce impressions that need to be measured by using a microscope with magnifications of up to 100X, although modern machines may be equipped with an image analysis system that enables the process to be automated.

The ultrasonic hardness test does not rely upon measuring the size of an impression. Instead, the test uses a Vickers diamond attached to the end of a metal rod. The rod is vibrated at its natural frequency by a piezoelectric converter and then brought into contact with the specimen surface under a small load. The resonant frequency is changed by the size of the impression produced and this change can be measured and converted to a hardness value.

The size of the impression is extremely small and the test may be regarded as non-destructive since it is non-damaging in most applications.

The micro-hardness test has a number of applications varying from being a metallurgical research tool to a method of quality control. The test may be used to determine the hardness of different micro-constituents in a metal, as shown in Fig.1. Where an impression would be damaging, for instance on a finished product, micro-hardness tests, particularly the ultrasonic test, may be used for quality control purposes. Micro-hardness testing also finds application in the testing of thin foils, case hardened items and decarburised components.

Portable hardness tests may be used where the component is too large to be taken to the testing machine or in on-site applications. It is useful on-site, for example, for checking that the correct heat treatment has been carried out on welded items or that welded joints comply with the hardness limits specified by NACE for sour service. There are three principal methods - dynamic rebound, Brinell or Vickers indentation or ultrasonic testing.

The Leeb hardness test uses dynamic rebound where a hammer is propelled into the test piece surface and the height of the rebound is measured. This gives a measure of the elasticity of the material and hence its hardness.

This type of test is typified by the 'Equotip' test, Fig.2, a trademark of Proceq SA. The Equotip tester comprises a hand-held tube that contains a spring loaded hammer. The device is cocked by compressing the hammer against the spring, the device is then positioned vertically on the test surface and the release button is pressed. The hammer strikes the surface, rebounds and the result displayed digitally. Generally the average of five readings is taken.

Micro-hardness and portable hardness test

The investigation of metallurgical problems in welds often requires the determination of hardness within a very small area or on components in service or too large to be able to test in a laboratory environment.Micro-hardness testing may be carried out using any one of three common methods and, as with the macro-hardness tests, measure the size of the impression produced by forcing an indentor into the specimen surface under a dead load, although many of the new test machines use a load cell system.

The three most common tests are the Knoop test, the Vickers test and the ultrasonic micro-hardness test.

The Knoop test uses a pyramidal indentor that gives an elongated diamond shaped impression with an aspect ratio of around 7:1, the Vickers test uses the pyramidal indentor described in the previous article (January/February 2005).

The Knoop test is rarely used in Europe where the Vickers test is the preferred method. The loads used for the tests vary from 1gmf to 1kgf and produce impressions that need to be measured by using a microscope with magnifications of up to 100X, although modern machines may be equipped with an image analysis system that enables the process to be automated.

The ultrasonic hardness test does not rely upon measuring the size of an impression. Instead, the test uses a Vickers diamond attached to the end of a metal rod. The rod is vibrated at its natural frequency by a piezoelectric converter and then brought into contact with the specimen surface under a small load. The resonant frequency is changed by the size of the impression produced and this change can be measured and converted to a hardness value.

The size of the impression is extremely small and the test may be regarded as non-destructive since it is non-damaging in most applications.

The micro-hardness test has a number of applications varying from being a metallurgical research tool to a method of quality control. The test may be used to determine the hardness of different micro-constituents in a metal, as shown in Fig.1. Where an impression would be damaging, for instance on a finished product, micro-hardness tests, particularly the ultrasonic test, may be used for quality control purposes. Micro-hardness testing also finds application in the testing of thin foils, case hardened items and decarburised components.

|

| Fig.1. Micro-hardness test |

Portable hardness tests may be used where the component is too large to be taken to the testing machine or in on-site applications. It is useful on-site, for example, for checking that the correct heat treatment has been carried out on welded items or that welded joints comply with the hardness limits specified by NACE for sour service. There are three principal methods - dynamic rebound, Brinell or Vickers indentation or ultrasonic testing.

The Leeb hardness test uses dynamic rebound where a hammer is propelled into the test piece surface and the height of the rebound is measured. This gives a measure of the elasticity of the material and hence its hardness.

This type of test is typified by the 'Equotip' test, Fig.2, a trademark of Proceq SA. The Equotip tester comprises a hand-held tube that contains a spring loaded hammer. The device is cocked by compressing the hammer against the spring, the device is then positioned vertically on the test surface and the release button is pressed. The hammer strikes the surface, rebounds and the result displayed digitally. Generally the average of five readings is taken.

|

| Fig.2. Equotip test |

To obtain a valid result, the position of the device, the flatness of the surface and the flexibility of the component all affect the accuracy of the results. Needless to say the skill and experience of the operator is one of the key factors in producing accurate hardness figures. The results are generally converted to give a hardness in Vickers or Brinell units.

The other type of portable hardness test in common use is the ultrasonic method described above. Commercially available machines are typified by the Microdur unit supplied by GE Inspection Technologies as shown in Fig.3. This type of equipment is electronically based and can be programmed to give hardness readings of any type - Vickers, Brinell, or Rockwell. Needless to say, any of these methods of hardness testing require regular calibration of the equipment, fully trained operators and well prepared surfaces.

The other type of portable hardness test in common use is the ultrasonic method described above. Commercially available machines are typified by the Microdur unit supplied by GE Inspection Technologies as shown in Fig.3. This type of equipment is electronically based and can be programmed to give hardness readings of any type - Vickers, Brinell, or Rockwell. Needless to say, any of these methods of hardness testing require regular calibration of the equipment, fully trained operators and well prepared surfaces.

|

| Fig.3. Ultrasonic testing using a Microdur unit |

Although there are several different methods of hardness testing the results can be compared and converted. The ASTM specification E140 contains conversion tables for metals - ferritic and austenitic steels, nickel alloys, copper and brass- for converting Vickers to Brinell or Rockwell or vice versa.

To end this post on hardness testing let us look at the significance of the results.

Hardness is related to tensile strength - multiplying the Vickers hardness number of a carbon steel by 3.3 will give the approximate ultimate tensile strength in N/mm 2 . A hardness traverse across a weld and its HAZs will therefore reveal how the tensile strength varies, as illustrated in Fig.4 which is for a work hardened aluminium alloy. In carbon or low alloy steels a hardness of above approximately 380HV suggests that the hard brittle microstructure, martensite, has been formed leading to the possibility of cold cracking during fabrication or brittle fracture in service. This fact has been recognised in the specification EN ISO 15614 Part 1 so that a maximum hardness of 380HV is permitted on a hardness traverse of a macro-section from a carbon steel procedure qualification test.

|

| Fig.4. Variation in tensile strength across a weld |

Relevant Specifications.ASTM E 10 Brinell Hardness of Metallic MaterialsASTM E 140 Hardness Conversion Tables for Metals. ASTM E 110 Portable Hardness Testing. ASTM E 384 Microhardness Testing of Metallic Materials. ASTM E 103 Rapid Indentation Hardness Testing. ASTM E 18 Rockwell Hardness Testing. ASTM E 92 Vickers Hardness of Metallic Materials. |

Thank you for sharing the information.

ReplyDeletemelt flow indexer

impact testing machine

This comment has been removed by the author.

ReplyDeleteAwesome article, it was exceptionally helpful! I simply began in this and I'm becoming more acquainted with it better! Cheers, keep doing awesome! https://imada.com

ReplyDeleteHey, Thank you so much for informing about Weld Testers. It is really such great information.

ReplyDeleteNice blog...Disc Polishing Machine All Model Chennai

ReplyDeleteThis comment has been removed by the author.

ReplyDelete